Case Study:

Successful RDC at Tutu Wellfield Superfund Site

DNAPL in Fractured Bedrock

Executive Summary

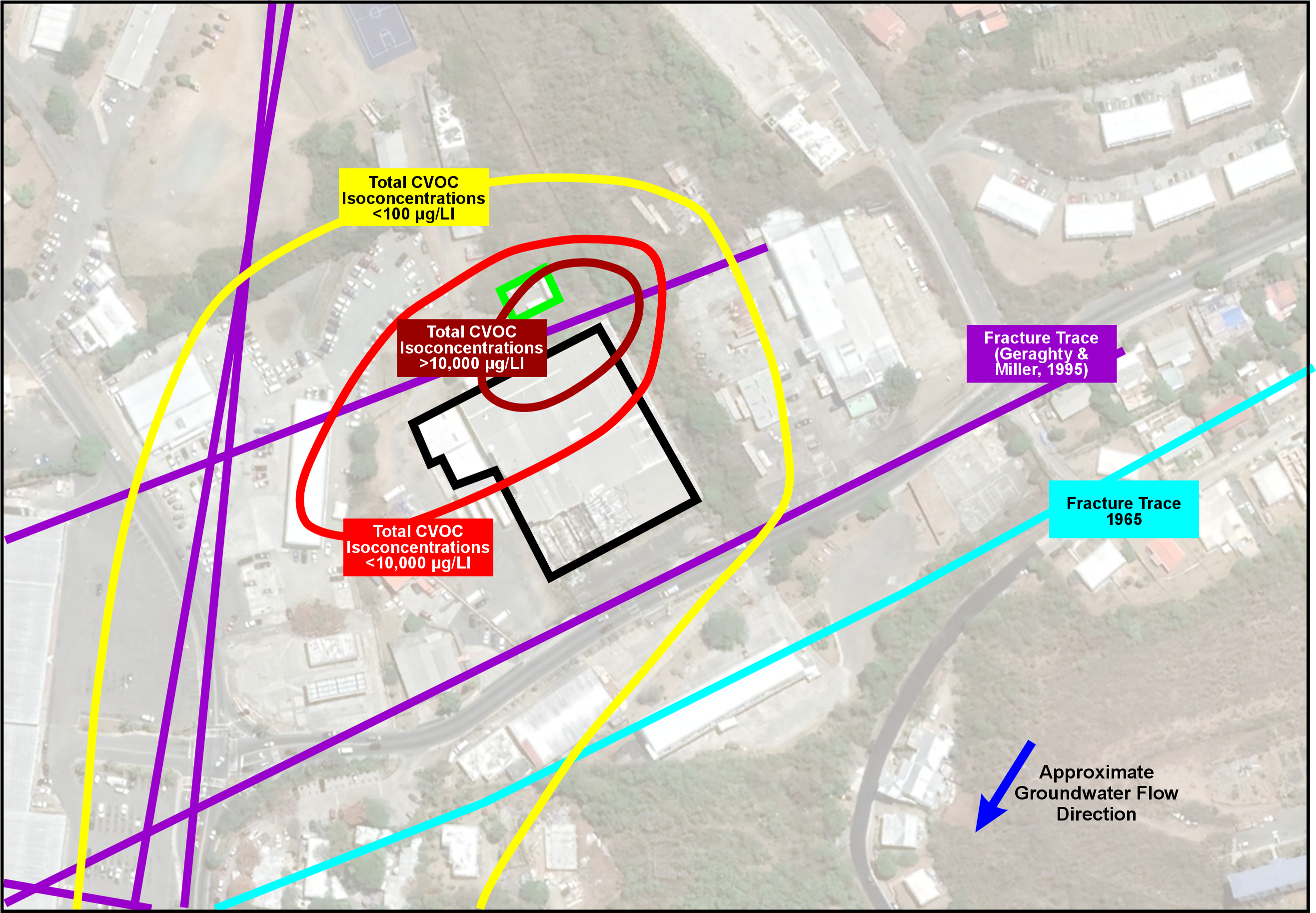

Operable Unit 2 (Site) of the Tutu Wellfield Superfund Site in St. Thomas, U.S. Virgin Islands (USVI) had a groundwater plume impacted with chlorinated volatile organic compound (CVOC) concentrations greater than 200 mg/L in some locations that threatened nearby municipal water supply wells (see graphic). HDR, one of the leading engineering firms in the world, was tasked with cost-effectively designing remediation to meet environmental clean-up standards and protect the community from harm.

HDR proactively recognized the need to increase certainty in its conceptual site model (CSM) and decided to leverage Aestus’ specialty electrical resistivity subsurface scanning technology (see field deployment photo below) and CSM update process for remedial design characterization (RDC).

Aestus guided HDR through its electrical hydrogeology CSM update process to realize new key CSM components:

- Located two, intersecting faults (confirmed via targeted drilling to be a high-permeability zone)

- Identified location of free-phase DNAPL for the first time in site history based on image guided drilling targets

- Mapped top of competent bedrock surface (contaminant flowpaths guided by bedrock)

HDR’s collaboration with Aestus resulted in an updated CSM, which provided drilling and remediation system targets in high-flux zones and increased HDR’s confidence in its remedial design for the site.

The Problem

Remediation of chlorinated volatile organic compound (CVOC) sites is challenging, particularly in complex geology involving fractured and faulted volcanic bedrock. Fractures and faults provide flowpaths for dense non-aqueous phase liquid (DNAPL) and related dissolved-phase contaminants to migrate vertically and laterally in groundwater. Locating and characterizing flowpaths is critical to remedial design since the bulk of contaminated groundwater is likely to be found in these hydraulically active areas. Successful remedial design/remedial action requires robust remedial design characterization to develop a data-rich and accurate CSM, which is not possible using untargeted drilling data alone.

Click on image to enlarge

Solution Approach

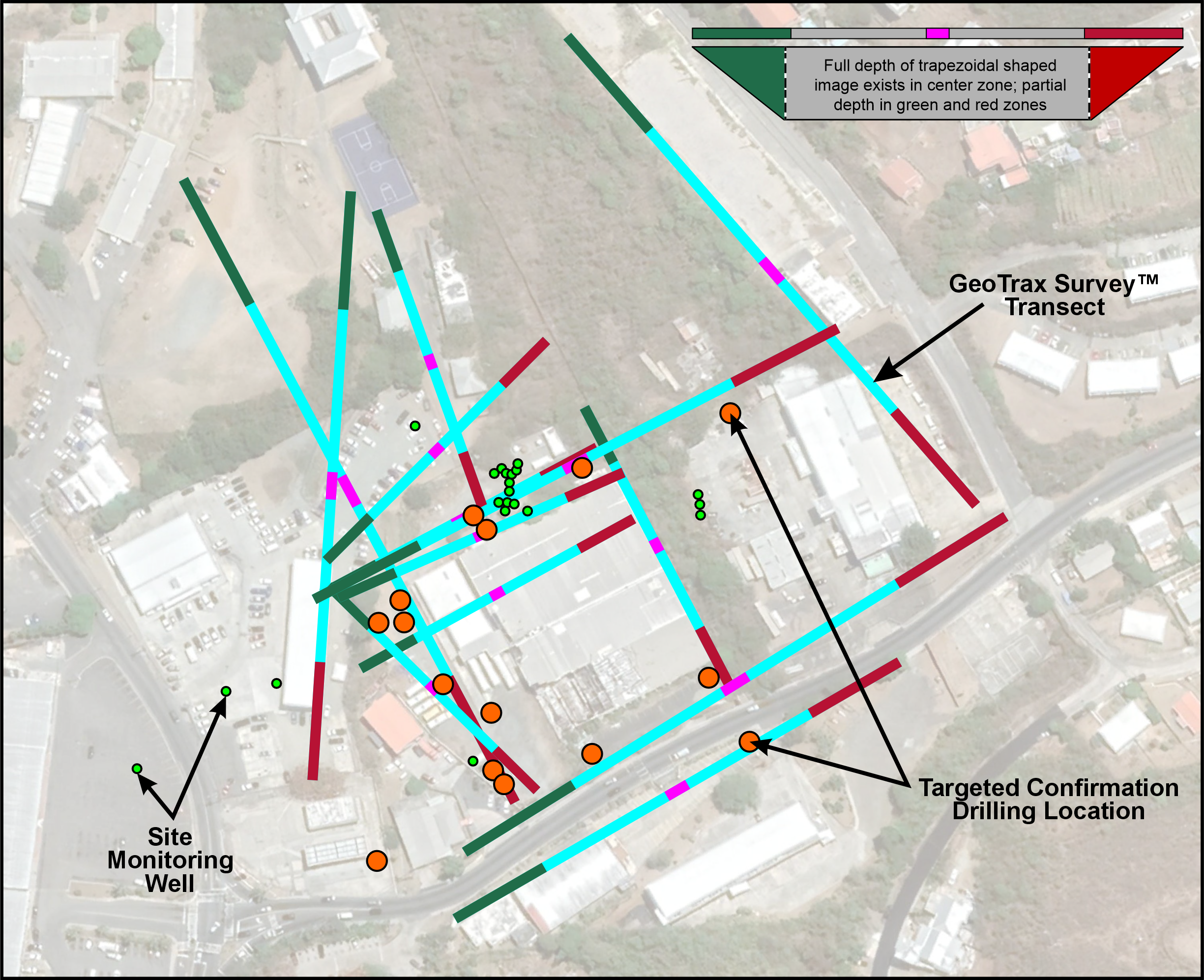

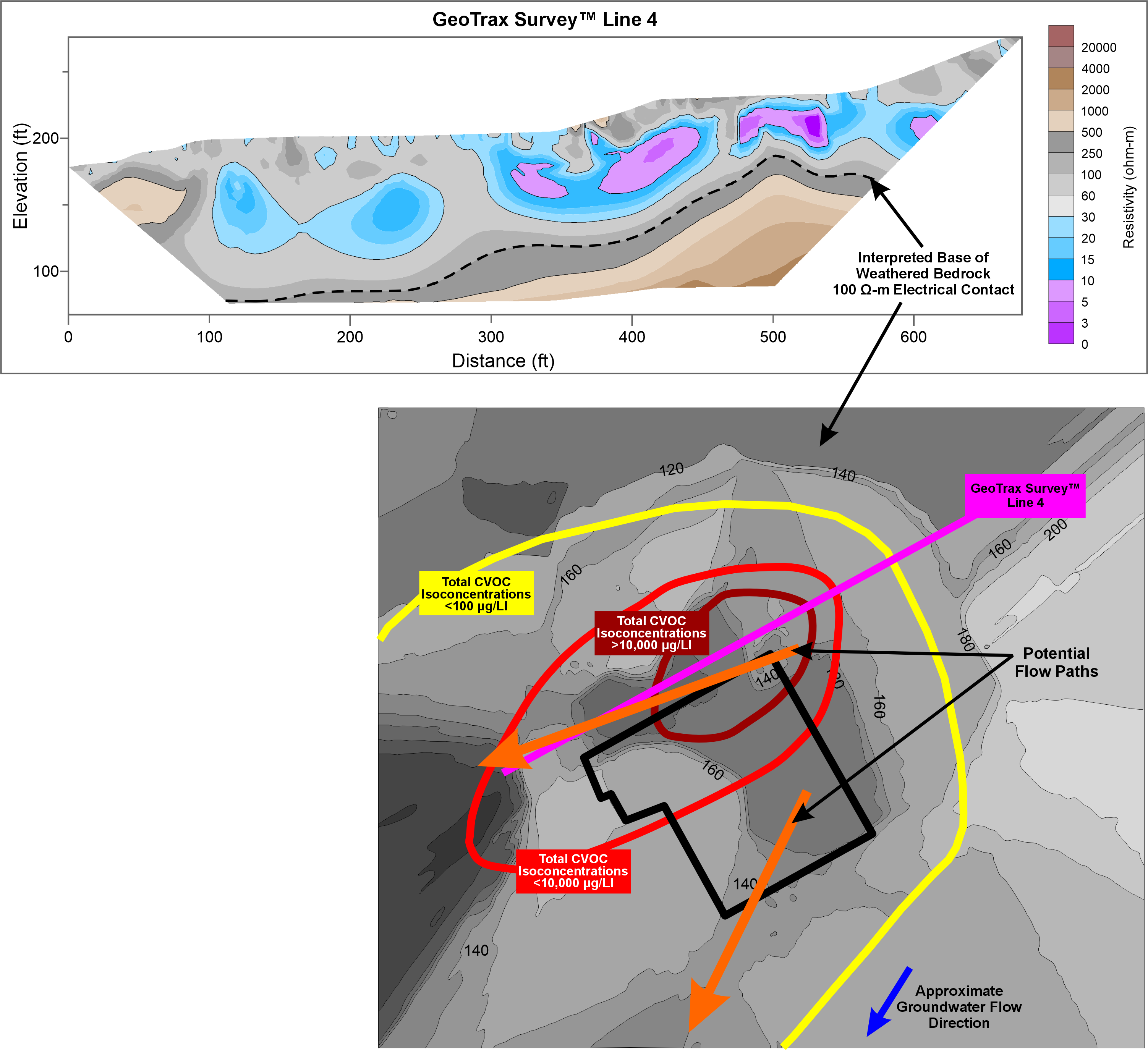

HDR deployed Aestus’ electrical hydrogeology scanning technology and 5-step CSM update process to locate DNAPL and aqueous phase CVOCs in groundwater and identify high-flux flowpaths. Aestus collected continuous 2D electrical images at locations shown in the graphic and integrated historical site data (i.e., geology, groundwater concentrations, etc.) into 2D figures and a 3D visualization model (Rockworks). Aestus and HDR worked collaboratively to leverage these integrated data sets and select targeted confirmation drilling locations (orange and green circles in the accompanying graphic) to target electrical anomalies and understand how these related to faults and fractures and preferential flowpaths as well as CVOC-related contaminant distribution.

Click on image to enlarge

Project Outcomes

Aestus was able to assist HDR with developing a data-rich CSM for the site that allowed HDR to focus remedial design/remedial action on high-flux subsurface pathways for more technical and cost-effective remediation. To further assist with remedial design, Aestus suggested additional drilling locations for HDR’s consideration as potential extraction and injection wells based on the updated CSM and electrical imagery.

HDR completed remedial design within three months of Aestus’ final report submission to keep the project moving forward quickly and in a very focused manner. HDR submitted the remedial design document in December 2023, and “Final Remediation Action” is expected in 2024 (EPA).

The evolution of this project demonstrated that the use of untargeted vertical borings and monitoring wells was not sufficient to locate and evaluate discrete faults and high-flux flowpaths. Aestus’ imaging technology and CSM update process allowed HDR and the EPA to save time and resources allocated to cleanup of Site by increasing certainty of the CSM and subsequent remedial design.

Specific CSM updates of significance included the following data and conclusions:

- Confirmation drilling targeting GeoTrax Survey image anomalous zone identified location of free-phase DNAPL for the first time in project history; allows focused remediation of source material at this location (see graphic)

- Interpreted two, intersecting faults (i.e., Fault A and B) shown in 3D by the pink and purple planes, respectively, in the graphic

- Targeted drilling confirmed highly fractured zones (red disks in the 3D image) present in rock cores at the intersection of Fault A and B

- Step tests in monitoring wells proximal to the intersection of faults mapped by Aestus had a high specific capacity

- Mapped top of competent bedrock surface (dark gray to light gray surface in the graphic)

- Identified potential flowpaths along depressions in the top of weathered andesite (orange arrows in the graphic)

Click on image to enlarge

Services Used on This Project

- Aestus GeoTrax Survey – Aestus imaged the subsurface and increased data density with its specialty 2D continuous electrical imaging technology.

- Aestus GeoTrax Viz – 2D and 3D integration of Aestus’ electrical imagery and other relevant site data into Rockworks 3D visualization software.

- Aestus GeoTrax CSM+ – Robust data interpretation process leveraging 2D and 3D multiple lines of evidence to allow interpretation of CSM updates and resulting recommendations to Aestus’ client.

Client Testimonial

“Aestus has been great to work with and we are very pleased with their value added to our project. Their GeoTrax CSM+ process helped us improve the conceptual site model (CSM) at the Tutu Wellfield Superfund Site in St. Thomas, U.S. Virgin Islands and allowed the project team to make better technical and budgetary decisions for the project. Specifically, Aestus’ integral GeoTrax Survey™ subsurface imaging process located fractures, faults, and a deformation zone where most of the groundwater flow and contaminant migration is occurring.

“Without this improved CSM understanding, we would not have been able to target our remedial design investigation by focusing monitoring and planned extraction wells in the high flow pathways so that our chlorinated solvent remediation can be more technically and cost effective.

“We would highly recommend Aestus for projects where the stakeholders want to enhance their site understanding to make more informed and effective decisions on characterization and remediation, with the goal of reaching site closure more quickly and cost effectively.”

– Demetrios Klerides, P.E., BCEE, Senior Project Manager / Professional Associate at HDR, Inc

Additional Project Information:

https://cumulis.epa.gov/supercpad/SiteProfiles/index.cfm?fuseaction=second.schedule&id=0202749