Case Study:

Mitigating Geohazard Risk in New Mexico

Potential Sinkhole Collapse in Karst Geology

Executive Summary

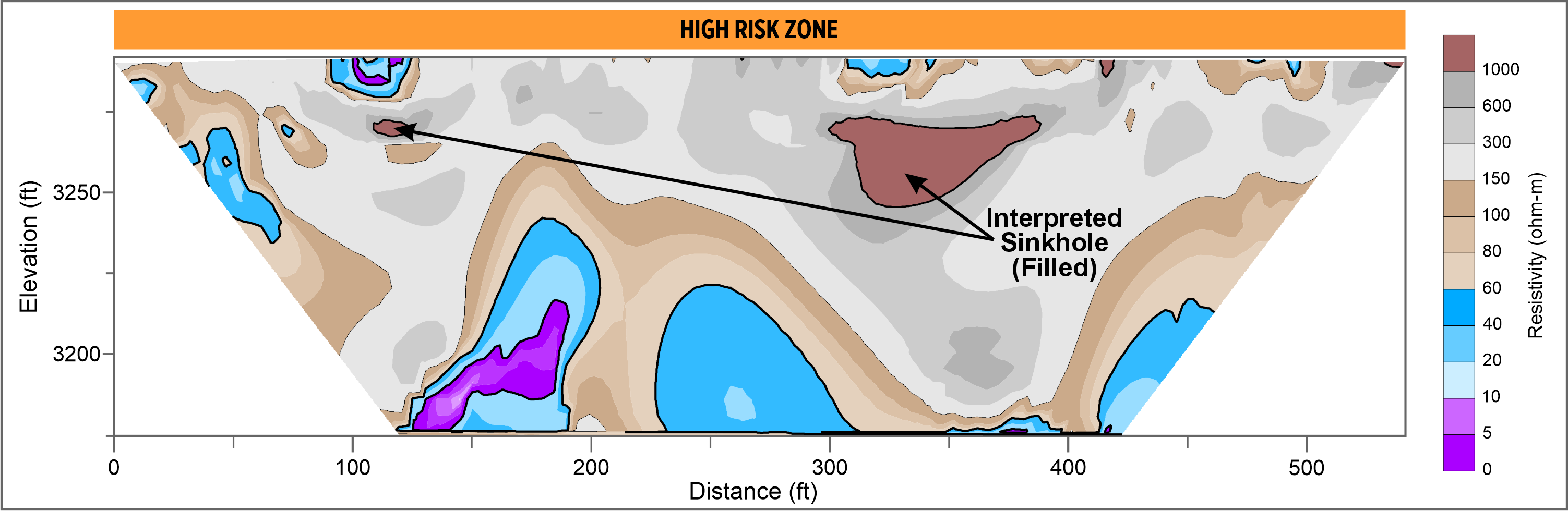

The Delaware Basin is a complex geologic setting with a reputation for high potential oil and gas production but simultaneously presents risk for drilling activities due to regional deformation (sinkholes, fractures, and faults) in karst geology. Some energy firms have lost expensive equipment due to a sinkhole developing under an operating well pad.

A leading oil and natural gas exploration and production company in the United States was exploring potential well pad sites in southeast New Mexico, within the Delaware Basin, and recognized the need to proactively increase certainty in drilling and operational safety by proactively working to mitigate the risk of these geohazards.

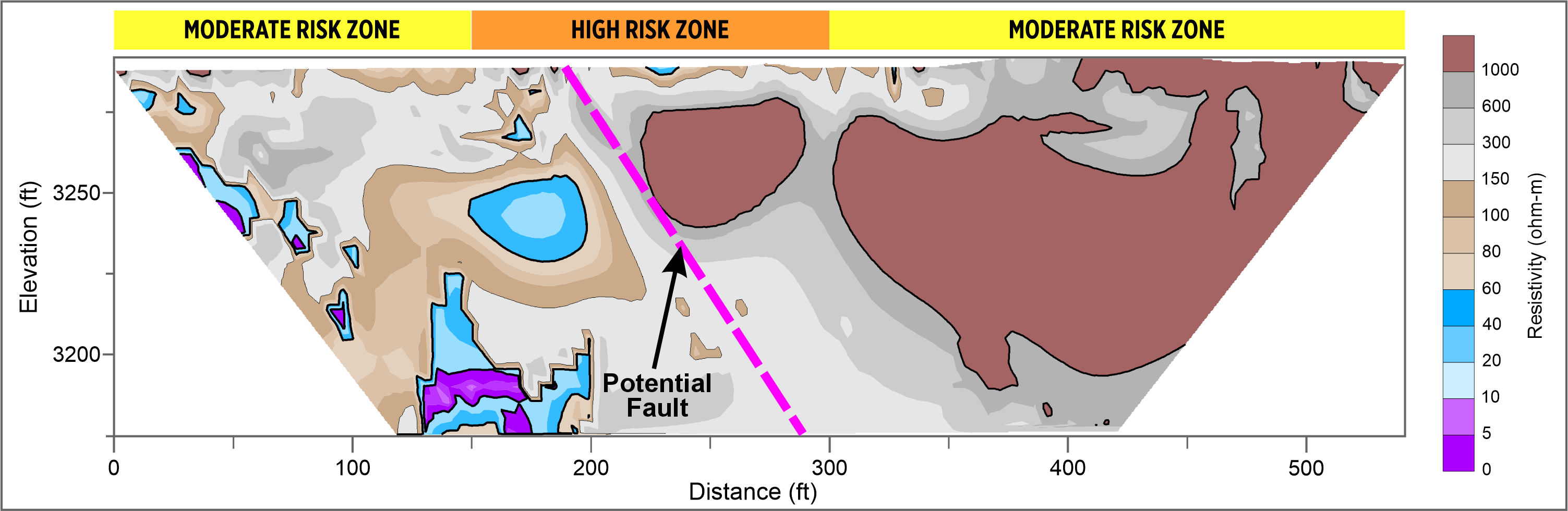

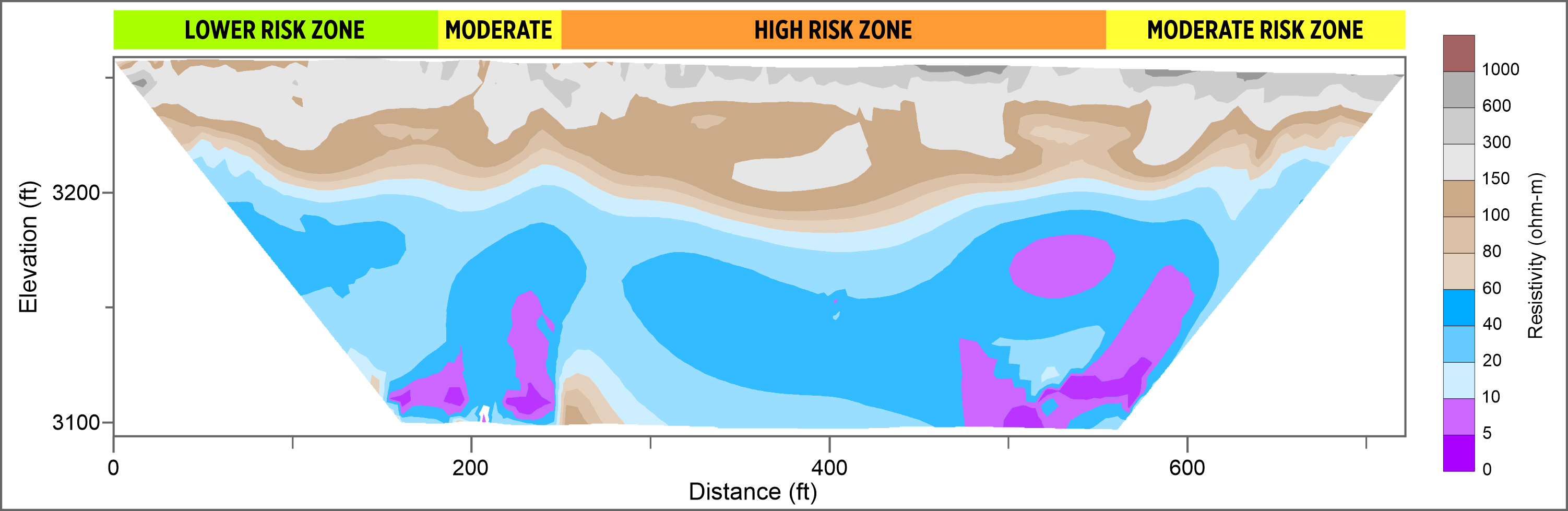

To address this challenge, this energy firm employed Aestus’ specialty electrical resistivity imaging (ERI) technology to scan proposed pad locations and better assess risk using actual field data, prior to any installation of heavy equipment which also causes vibrations during operation. Aestus imaged proposed pad locations and determined areas of low, moderate, and high-risk zones based on interpretation of its electrical imagery as an indicator of sinkhole potential. Aestus’ technology and process helped our client make better informed technical and business decisions regarding risk mitigation for these important projects.

The Problem

To address the challenge of unknown subsurface conditions due to regional karst geology and accompanying sinkhole potential, this energy firm employed Aestus’ specialty electrical resistivity imaging (ERI) technology to scan proposed pad locations and better assess risk prior to any installation of heavy and/or vibrating equipment. Aestus imaged proposed pad locations and determined areas of low, medium, and high risk.

Click on image to enlarge

Solution Approach

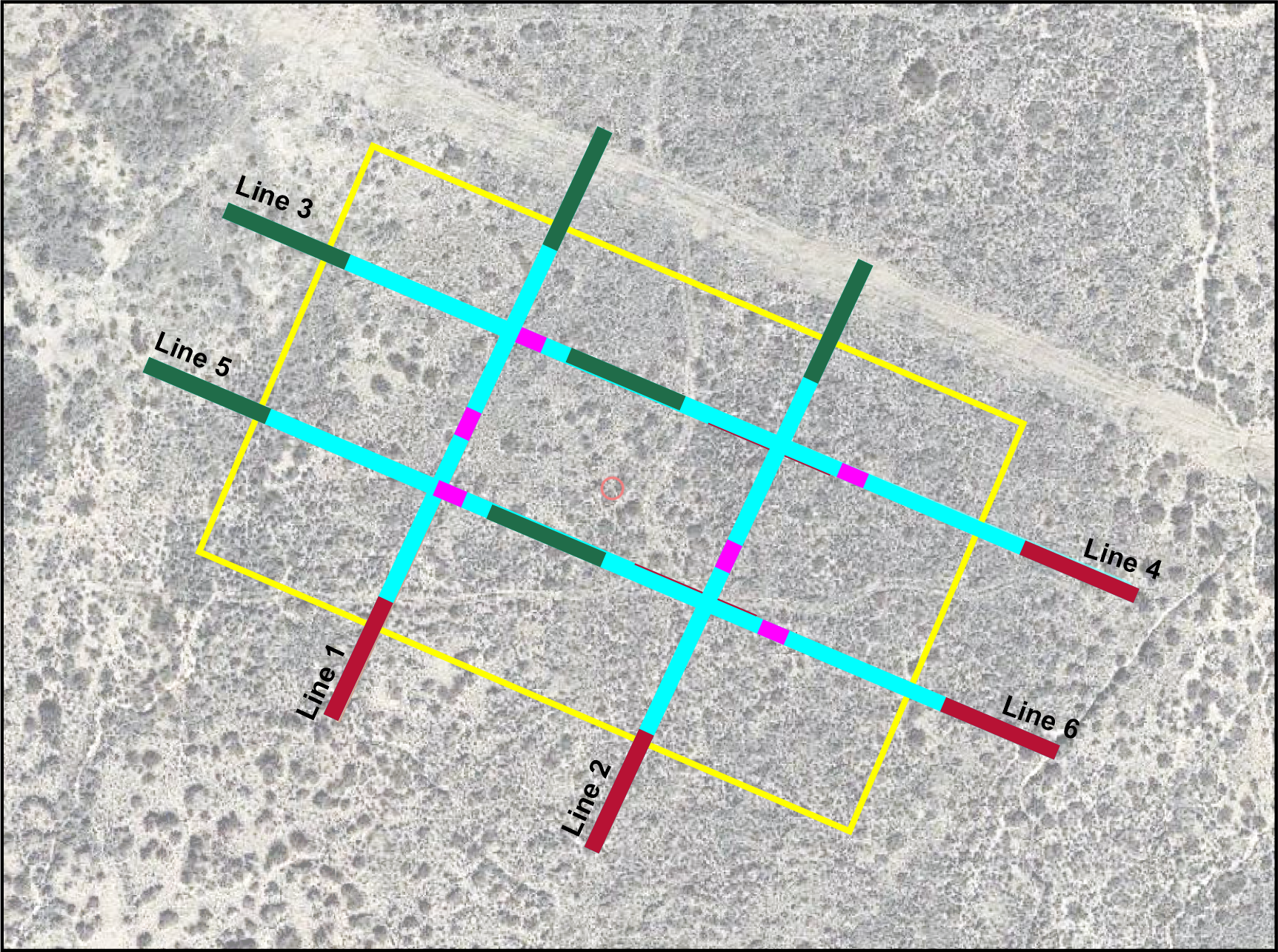

Aestus was selected to perform a non-intrusive and surface deployed scan (Aestus GeoTrax Survey) of proposed drill pad locations to provide more certainty relative to estimating risk of sinkhole collapse. Multiple continuous 2D electrical images (i.e., installed at the transect locations shown in the graphic) were integrated with regional geologic information into a 3D visualization model.

Click on image to enlarge

Project Outcomes

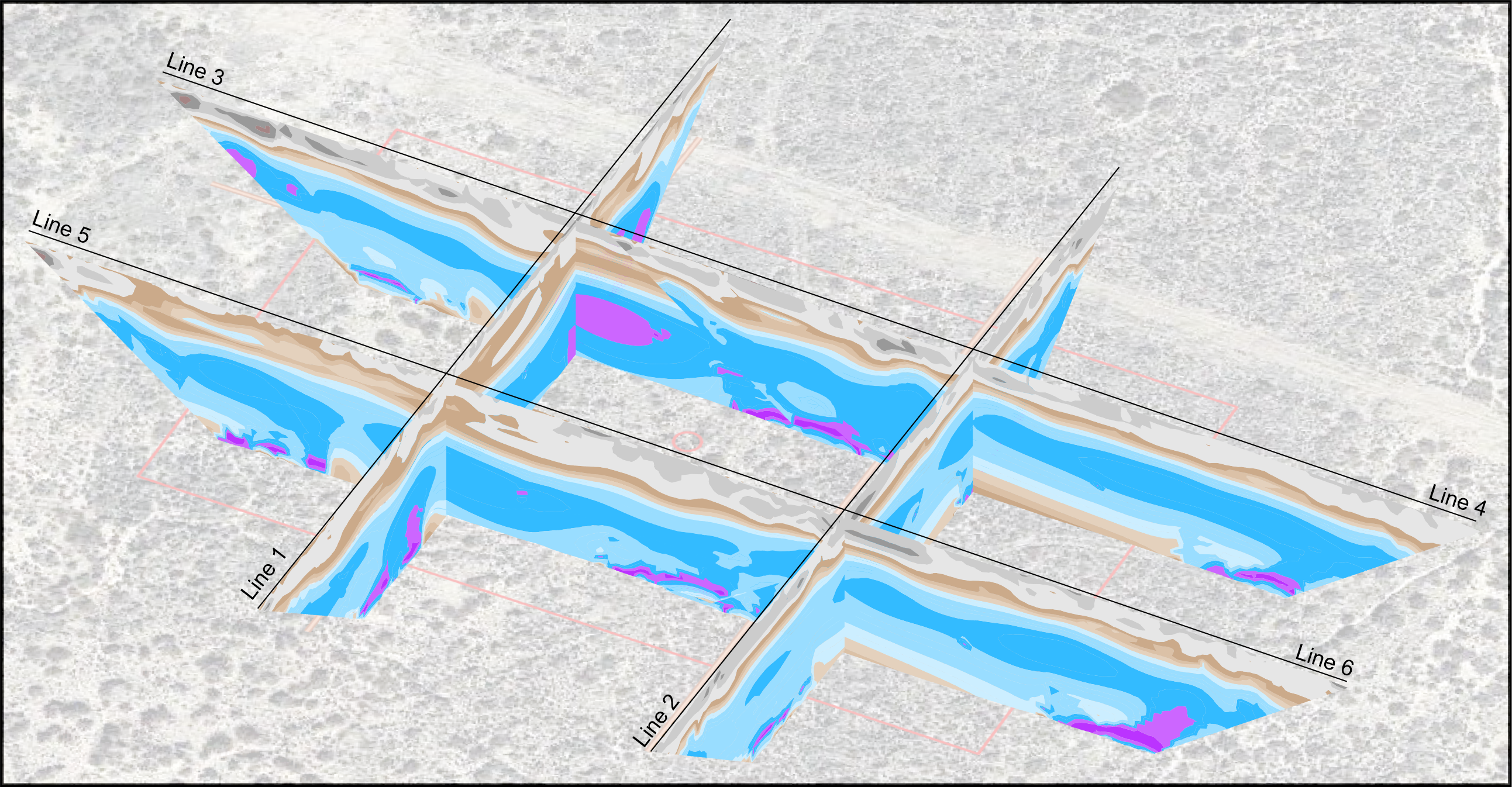

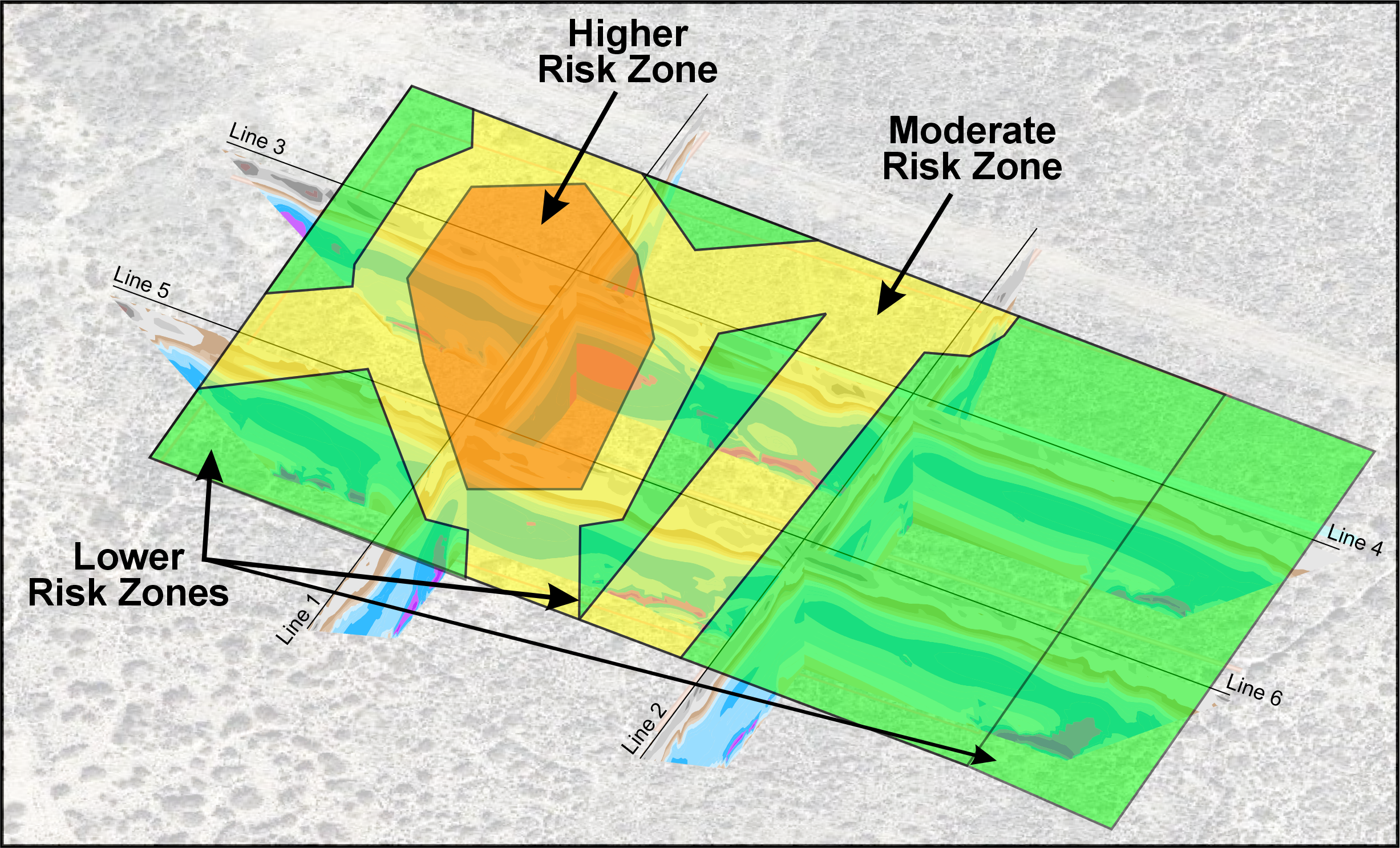

Aestus’ ultra-high resolution continuous 2D imagery, 3D data visualization, and data analysis increased the energy firm’s confidence in understanding subsurface geohazards (sinkholes, fractures, faults, and dipping geologic beds).

Specifically, Aestus’ collaborative process with the energy firm resulted in identification of lower risk zones deemed more appropriate to proceed with drilling/pad installations as well as higher risk zones deemed as less appropriate for drilling/pad installations (see example 2D and 3D graphical outputs showing estimated low, moderate, and high risk zones below the proposed drilling pad location).

Click on image to enlarge

Services Used on This Project

- Aestus GeoTrax Survey – Aestus imaged the subsurface and increased data density with its specialty 2D continuous electrical imaging technology.

- Aestus GeoTrax Viz – 2D and 3D integration of Aestus’ electrical imagery and other relevant site data into Rockworks 3D visualization software.