Case Study:

Focused Remediation Saves Refinery $20+ Million

LNAPL in Paleochannels at 500+ Feet Deep

Executive Summary

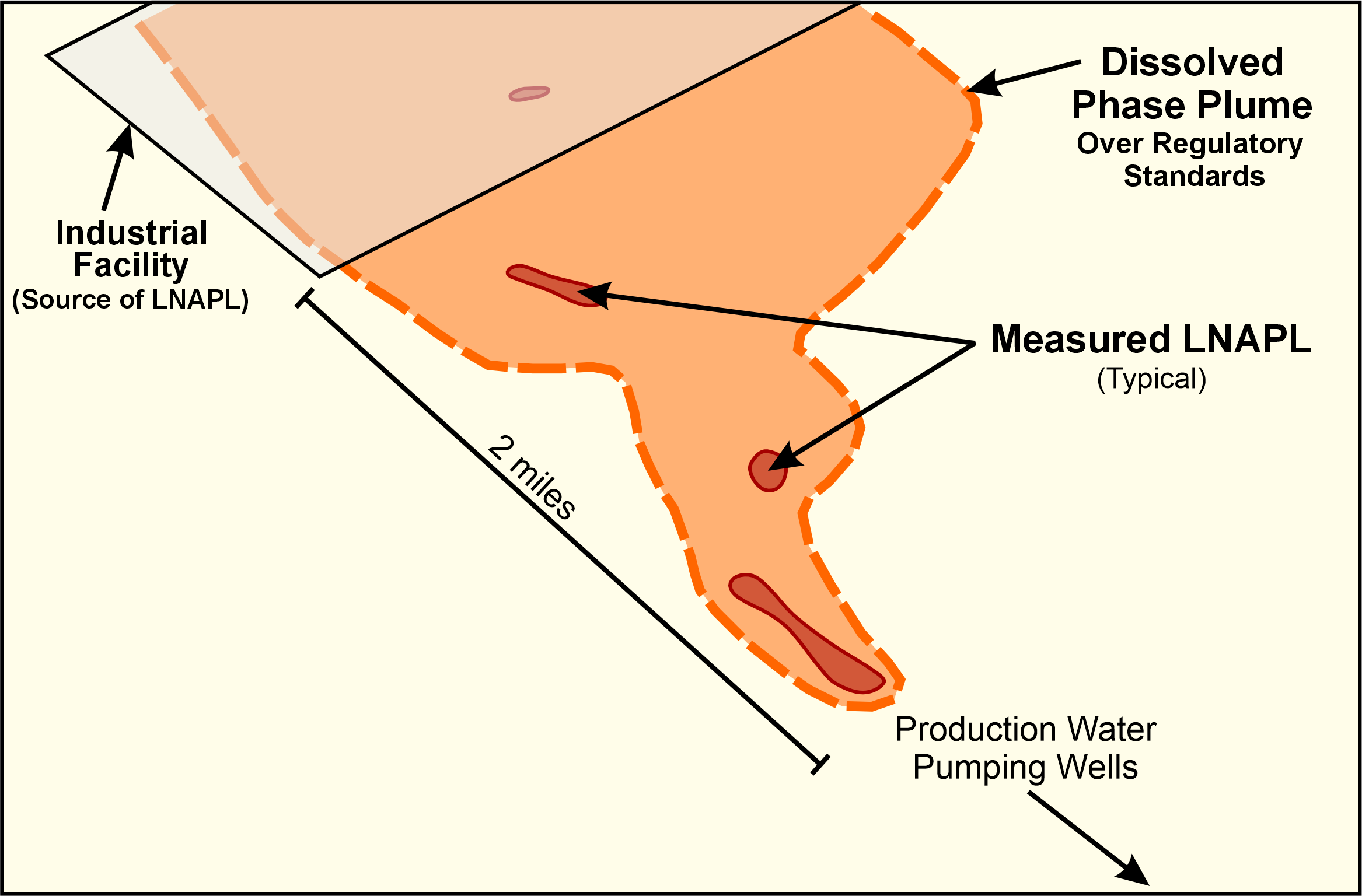

A refinery site in the southern United States identified potential past petroleum hydrocarbon releases into the ground in proximity to the local aquifer where the static groundwater table is approximately 300+ feet below ground surface (BGS). Free-phase light non-aqueous phase liquid (LNAPL) thicknesses had been measured at 10+ feet in some locations and as distal as two miles from the suspected source zone. Significant time and costs were incurred to characterize the relevant area and remediate LNAPL impacts for 15+ years.

Aestus and its energy industry client determined it to be impractical and financially challenging to continue trying to characterize the subsurface with monitoring wells alone, given that they needed to be installed to ~500 feet BGS at an approximate cost $180K per well. Additionally, it was strongly suspected that discrete paleochannels were likely influencing subsurface LNAPL distribution and would be nearly impossible to find via untargeted 1D drilling techniques.

The client’s project team decided to use Aestus’ conceptual site model (CSM) update process to generate continuous 2D subsurface images and guide future drilling and remediation efforts. Their collaboration with Aestus resulted in successfully mapping discrete paleochannels, which were confirmed via targeted drilling into these flux zones. Aestus’ client estimated that potentially ~$20+ million was saved via the scan first, then drill approach, which created more certainty for making decisions on the project.

The Problem

The project team was tasked with determining the extent and location of subsurface LNAPL and related dissolved phase issues to avoid impacts for the surrounding community and comply with regulatory standards. The relevant aquifer consisted of gravels, sands, silts, and clay sediments deposited by ancient river systems in paleochannels, which provide preferential subsurface flowpaths and may allow constituents of interest. LNAPL thicknesses had been measured at 10+ feet in some locations (groundwater table depth of ~320 feet BGS) and as distal as two miles from the suspected source zones.

Considerable time and costs had been incurred to characterize the relevant area using traditional methods and remediate LNAPL impacts for 15+ years. Characterizing the groundwater plume at this site was complicated by constituents moving through discrete and mostly unidentified paleochannel flowpaths, a large scope area (i.e., square miles), and lack of sufficient CSM data density due to the technical and financial impracticability of using conventional industry techniques with untargeted 1-D monitoring wells.

Click on image to enlarge

Solution Approach

The refinery’s project team recognized the importance of characterizing suspected paleochannels and stratigraphy at the site to have an accurate CSM and to formulate a successful, practical, and fiscally sound remedial strategy.

The project team decided to employ Aestus’ electrical hydrogeology tools for remedial design characterization (RDC) and updating the CSM to optimize characterization and remediation efforts.

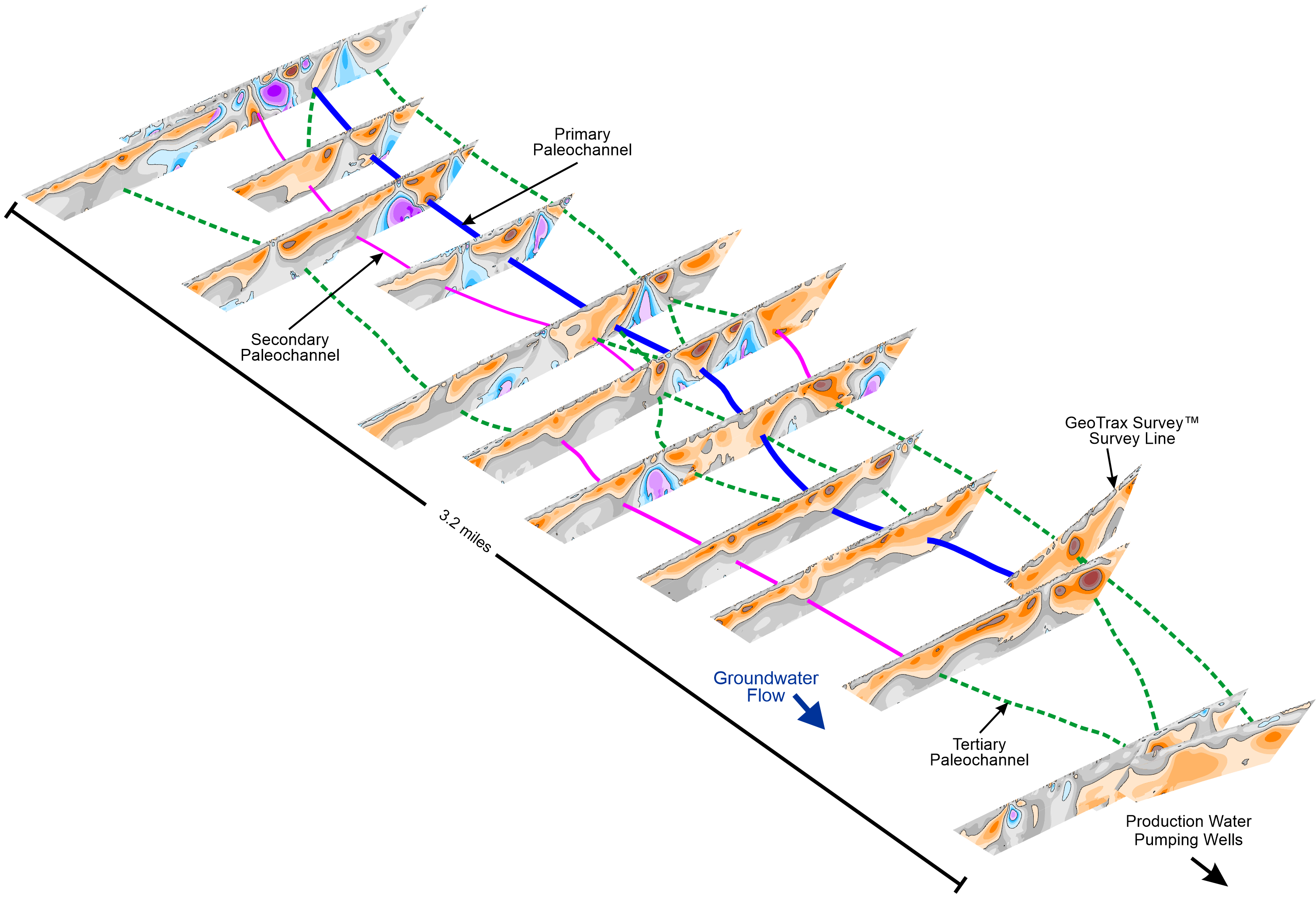

Aestus used its surface-deployed specialty electrical resistivity imaging to visualize the subsurface, covering an area of approximately 4.2 square miles (roughly 3.2 miles long by 1.3 miles wide) and to depths of 540 feet BGS.

Click on image to enlarge

Project Outcomes

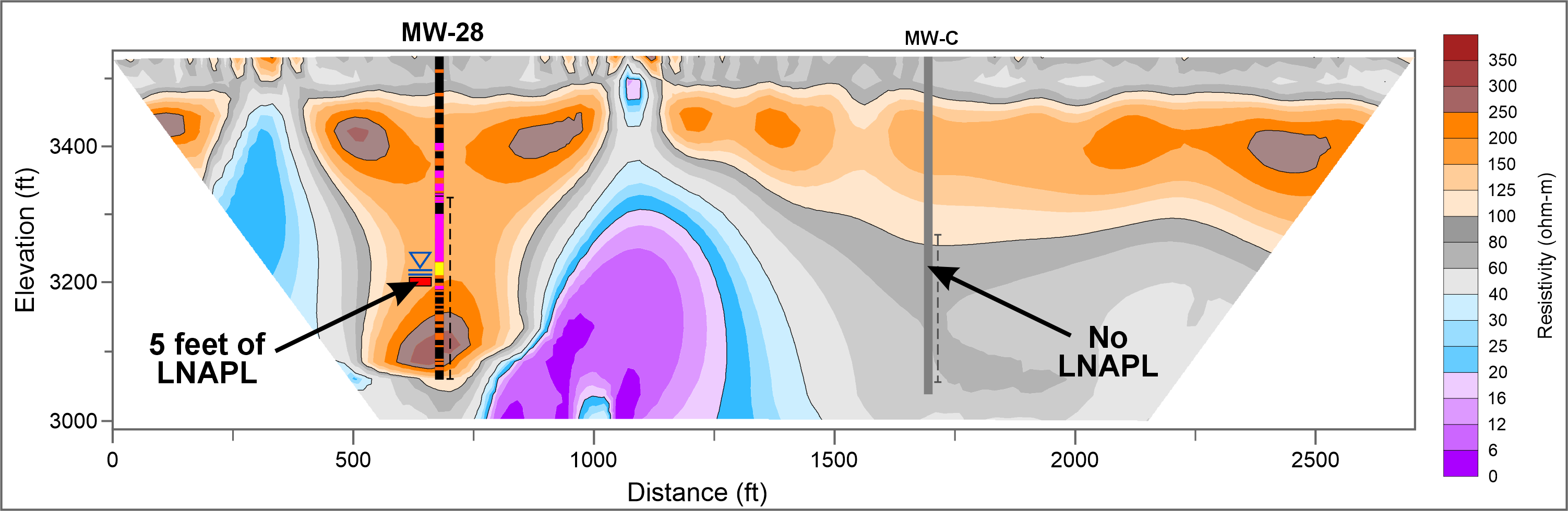

Aestus’ electrical imaging techniques yielded suspected locations of paleochannels across the site (i.e., blue and dashed-blue lines in the graphic) a number of which were drilled and confirmed via targeted drilling/wells.

A primary paleochannel was confirmed as a major transport mechanism of LNAPL based on the installation of targeted monitoring well MW-28 (shown in the accompanying graphic). MW-28 confirmed the presence of LNAPL and identified large intervals of gravels, sands, and instances of rounded gravel (indicative of river deposition) in the boring log.

In addition to mapping paleochannel flowpaths and identifying areas for focused remediation, the project team leveraged Aestus and its integrated data sets in 2D and 3D to achieve additional project outcomes:

- Delineate deeper clay formation, which was determined to impede vertical migration of contaminants

- Target distal, downgradient sentinel wells to monitor groundwater impacts along paleochannel flowpaths (the most likely location of contaminant migration)

- Facilitate data dense inputs to help constrain numeric groundwater model boundaries (work performed by others). The output of this model was used by our client to determine which downgradient water supply wells should be shut off to avoid influencing plume movement through paleochannel flowpaths.

- Start evaluating levels of naturally occurring bioactivity in impacted zones; data collected to date indicates elevated bioactivity is likely occurring within the relevant subsurface plume center of mass and less so on the downgradient distal end of the plume.

Project Financial Outcomes

The refinery’s project team estimated that roughly $20+ million was potentially saved on RDC facilitated by the use of Aestus’ technologies and processes, versus traditional site characterization efforts coupled with the installation of additional untargeted, high-cost monitoring wells. Updating the CSM with continuous electrical image data and targeted well installation increased certainty in the subsurface structure and contaminant extents, providing better data for our clients to make better decisions relative to remediation strategy.

Click on image to enlarge

Services Used on This Project

- Aestus GeoTrax Survey – Aestus imaged the subsurface and increased data density with its specialty 2D continuous electrical imaging technology.

- Aestus GeoTrax Viz – 2D and 3D integration of Aestus’ electrical imagery and other relevant site data into Rockworks® 3D visualization software.

- Aestus GeoTrax CSM+ – Robust data interpretation process leveraging 2D and 3D multiple lines of evidence to allow interpretation of CSM updates and resulting recommendations to Aestus’ client.