ELECTRICAL RESISTIVITY IMAGING

Scan first. Drill smart.

Detect anomalies, locate contaminants, and know where to drill in less time with our noninvasive, ultra-high data density subsurface imaging

Targeted Drilling

"Drillable" images are produced from tens of thousands of data points

Higher Data Quality

More robust and accurate subsurface image than standard ERI

Geology Independent

Works in clay, silt, sand, gravels, bedrock, and more

Most Sites Are Hydrogeologically Complex, and Accurate CSM Cannot Be Developed Without a Large Number of Field Data Points.

Not to mention, the process of detecting and remediating contaminants at environmental sites adds complicating factors.

Traditional soil and groundwater sampling techniques, like ground-penetrating radar and conventional electrical resistivity imaging (ERI), might not be the best options. You need a proven non-intrusive screening approach that works in challenging and complex hydrogeologic environments, and sometimes with added contaminant and bioactivity signatures. You need our robust data integration and experienced interpretation, combined with targeted confirmation drilling.

So how will you know where to drill?

Scan first and drill smart with Aestus GeoTrax Survey.

With Aestus GeoTrax Survey subsurface imaging, you can detect anomalies, locate contaminants, and know where to drill. You will gain a better understanding of subsurface challenges and risks, reduce uncertainties, and make better decisions.

Applications

Sinkhole Potential (geohazards)

Map Contaminant Distribution

Saline Intrusion

Detection

Geologic Mapping

Lithologic Controls

Target Water

Supply Wells

Managed Aquifer

Recharge Monitoring

Bioactivity

Assessment

Applications

Sinkhole Potential (geohazards)

Map Contaminant Distribution

Saline Intrusion Detection

Geologic Mapping

Lithologic Controls

Target Water Supply Wells

Managed Aquifer Recharge Monitoring

Bioactivity Assessment

Drill smarter, not harder.

With our fast, non-intrusive screening approach to site inspection.

- No chemical samples collected

- Higher data density

- Nonintrusive (no drilling, no digging)

- Yields focused confirmation drilling targets

- Improves subsurface certainty and project outcomes

Why Are You Still Relying on Insufficient Site Data?

Our ultra-high resolution site data helps you see subsurface issues before you drill.

The GeoTrax CSM+ Process:

Visualize. Scan. Integrate. Confirm.

Through our proprietary process that combines your existing data with our ultra-high resolution data, we locate zones of interest and increase certainty of subsurface issues for better project outcomes at lower cost and in less time.

Legend

ERI

Data Integration

CSM

3-4 Weeks Prior to Fieldwork

Visualize Existing Data

You send us your existing site data, and we visualize it in 3D to plan the most effective way to scan your site.

1-2 Weeks of Fieldwork

Conduct Fieldwork

We conduct an ultra-high resolution electrical scan with GeoTrax Survey.

8 Weeks After Fieldwork

Deliver Interim CSM Report

We integrate the two data sets in 2D and 3D, deliver an interim report with hypothesis. We then collaborate with you to select confirmation drilling locations.

Determined by You

Conduct Confirmation Drilling

You conduct targeted drilling and sampling, testing the CSM hypothesis, and send final confirmation drilling data back to us.

8 Weeks After We Receive Your Confirmation Data

Deliver Final CSM+ Report

Our final CSM+ report integrates all confirmation data and delivers it to you in 3D ultra-high resolution, so you can make better decisions and move your project forward.

*Schedules are approximate and are for reference only. We will provide project-specific schedules during the proposal phase.

Visualize Better Data

Move forward with

more certainty

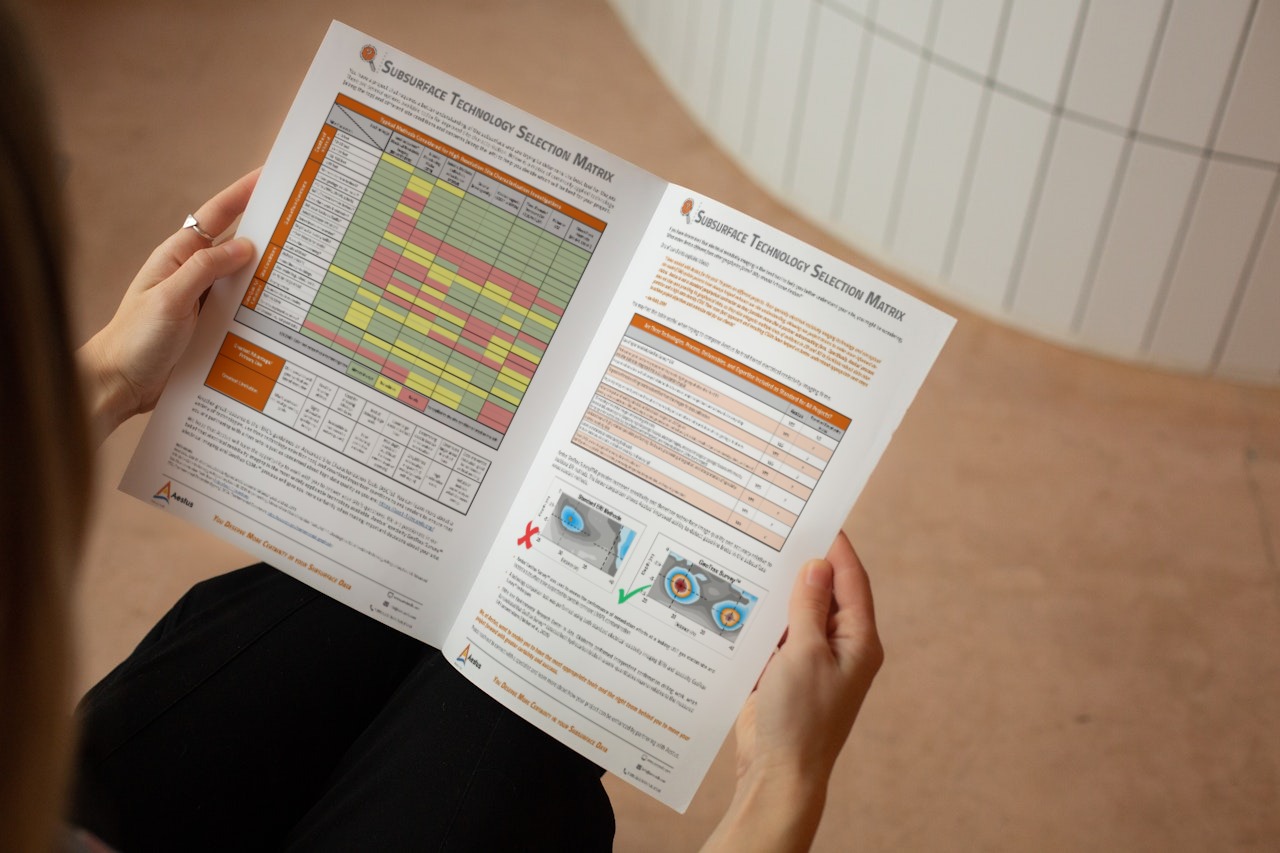

Share your information, and we’ll send you a free Technology Selection Matrix to help you decide what subsurface technology(ies) are appropriate to help you based on your project size and objectives.