CONCEPTUAL SITE MODELS

Focused remediation for faster site closure

Create more complete and accurate conceptual site models with Ultra High-Resolution Site Characterization

Faster Characterization

Finish the entire process, including focused client confirmation drilling, in as little as six months instead of years or even decades.

Better Data

Follow up or other site work is typically faster, more successful, and less costly with ultra-high resolution site data.

Fewer Liabilities

Better data leads to better decisions about site work, which means reduced potential for trailing environmental or other liabilities after project budgets are closed.

Too many environmental sites are stuck on a characterization-remediation treadmill.

This can last years or even decades, significantly increasing the cost and time to site closure. Why? It's virtually impossible to develop an accurate conceptual site model (CSM) using data from only tens of wells.

Get off the treadmill with Aestus GeoTrax CSM+.

More complete and accurate conceptual site models require higher data density.

Target contaminated areas, and close your site faster, safer, and cheaper.

Here's how GeoTrax CSM+ works:

Collect the Data

With Aestus GeoTrax Survey, using our enhanced, proprietary electrical resistivity imaging that provides ultra-high data density. Think of thousands of points of data, not a hundred points of data.

Visualize and

Interpret the DataUsing Aestus GeoTrax Viz 3D visualization and integration, we generate a final report and ultra-high-resolution conceptual site model (CSM+).

Close Site Faster

Now that you have a more complete and accurate picture of what's below the surface, you can use the data to make better decisions, close your site faster and cheaper. You can also guide ongoing monitoring and remediation with Aestus GeoTrax Monitoring.

Aestus GeoTrax CSM+ provides a more complete and accurate picture of your site's subsurface with the data you need to make faster, more cost-effective decisions and move your project forward.

Applications

Sinkhole Potential (geohazards)

Map Contaminant Distribution

Saline Intrusion

Detection

Geologic Mapping

Lithologic Controls

Target Water

Supply Wells

Managed Aquifer

Recharge Monitoring

Bioactivity

Assessment

Applications

Sinkhole Potential (geohazards)

Map Contaminant Distribution

Saline Intrusion Detection

Geologic Mapping

Lithologic Controls

Target Water Supply Wells

Managed Aquifer Recharge Monitoring

Bioactivity Assessment

IT'S NEVER TOO LATE TO ACHIEVE FOCUSED REMEDIATION AND GET THE DATA YOU NEED FOR BETTER DECISIONS.

Utilize Aestus GeoTrax CSM+ at any time in your project to expedite site closure at a lower overall cost.

Scan First. Drill Smart.

Our proprietary electrical resistivity subsurface imaging capabilities facilitate a scan first, then drill approach for conceptual site models. This allows our clients to drill smarter—avoiding the conventional drilling blind approach to site characterization—and target the drilling work.

Data Integration. 3D Visualization.

Aestus GeoTrax Viz provides geospatial integration resulting in 2D and 3D visualization of our ultra-high data density GeoTrax Survey subsurface imagery with historical and follow-up confirmation drilling data.

Ultra-high Data Density.

Our non-invasive scanning process typically delivers tens of thousands of real field data points—orders of magnitude more than traditional methods.

Improved Interpolation.

We provide data/imagery along a continuous GeoTrax Survey transect line rather than only from discrete points, such as soil borings or wells.

This improves interpolation between traditional discrete data points and assists in confirming or redefining the conceptual site model.

Better Data, Better Decisions.

Our GeoTrax CSM+ process facilitates the development of a new ultra-high data density conceptual site model for the project site, which typically creates a better understanding of:

- Environmental contaminant distribution

- Presence of natural attenuation or enhanced bioactivity

- Hydrogeology

- Preferential contaminant flow pathways

The GeoTrax CSM+ Process:

Visualize. Scan. Integrate. Confirm.

Through our proprietary process that combines your existing data with our ultra-high resolution data, we locate zones of interest and increase certainty of subsurface issues for better project outcomes at lower cost and in less time.

Legend

ERI

Data Integration

CSM

3-4 Weeks Prior to Fieldwork

Visualize Existing Data

You send us your existing site data, and we visualize it in 3D to plan the most effective way to scan your site.

1-2 Weeks of Fieldwork

Conduct Fieldwork

We conduct an ultra-high resolution electrical scan with GeoTrax Survey.

8 Weeks After Fieldwork

Deliver Interim CSM Report

We integrate the two data sets in 2D and 3D, deliver an interim report with hypothesis. We then collaborate with you to select confirmation drilling locations.

Determined by You

Conduct Confirmation Drilling

You conduct targeted drilling and sampling, testing the CSM hypothesis, and send final confirmation drilling data back to us.

8 Weeks After We Receive Your Confirmation Data

Deliver Final CSM+ Report

Our final CSM+ report integrates all confirmation data and delivers it to you in 3D ultra-high resolution, so you can make better decisions and move your project forward.

*Schedules are approximate and are for reference only. We will provide project-specific schedules during the proposal phase.

Visualize Better Data

Move forward with

more certainty

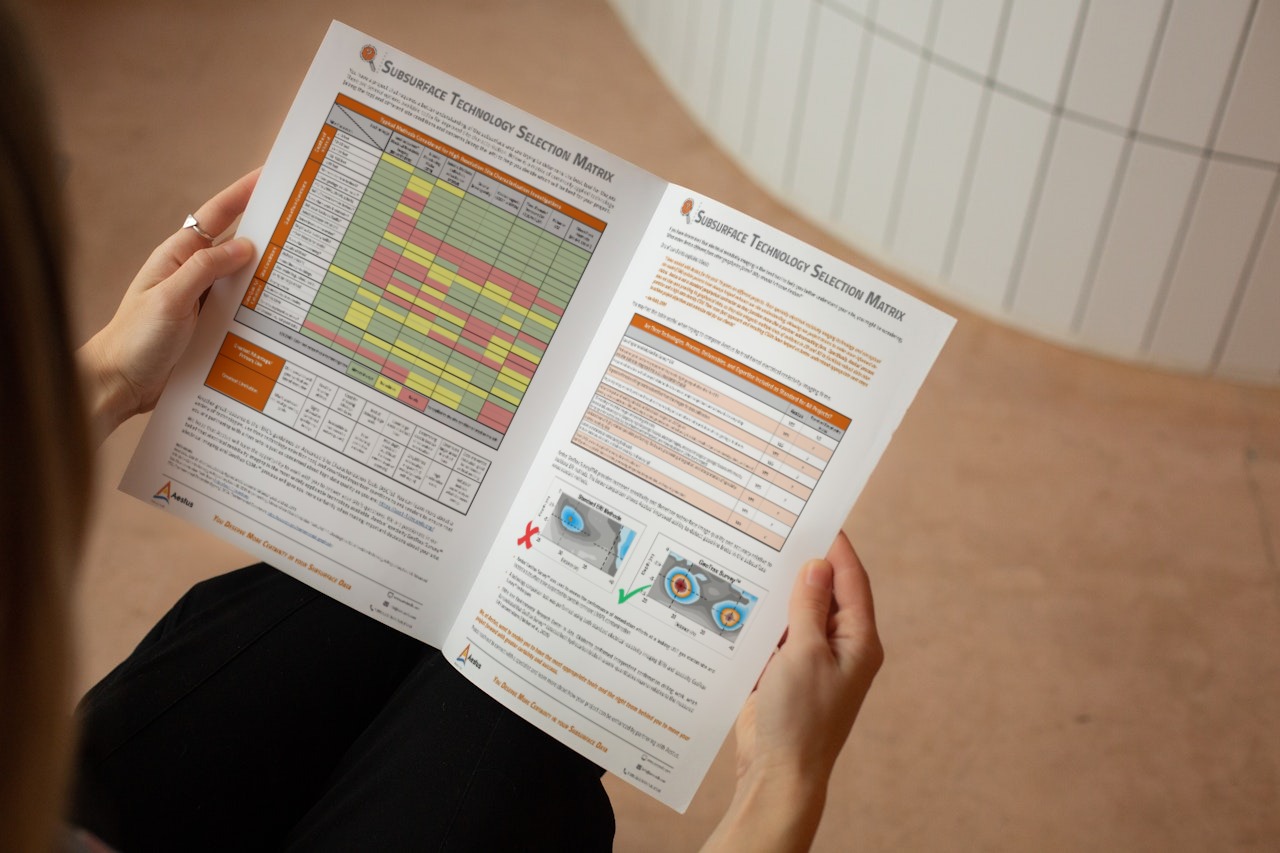

Share your information, and we’ll send you a free Technology Selection Matrix to help you decide what subsurface technology(ies) are appropriate to help you based on your project size and objectives.